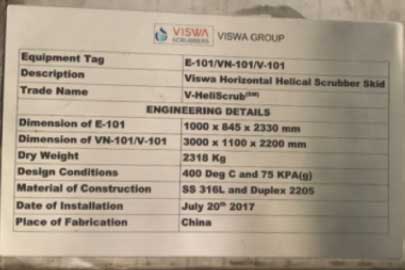

V-HELISCRUB- HORIZONTAL SCRUBBER

Now fitted on vessel at Chengxi shipyard

| V-Heliscrub V/S Other Vertical Scrubbers |

|

|

V-Heliscrub |

| Footprint |

50% smaller |

| Weight |

50% lighter |

| Cost |

30% lower |

| Installation Time* |

Minimal (50% less time) |

- Smaller size and footprint, Lighter and cheaper than Vertical Designs

- Compact design than vertical scrubbers due to higher allowable velocities

- 2 times higher velocity than vertical scrubbers

- 30% less diameter than vertical scrubbers

- Easy retrofit & Flexible design

- Easy maintenance

- High dust/particle handling capacity

- Reduced scrubber liquid consumption

- Venturi scrubber, cyclonic scrubber & spray scrubber effects achieved

Unique Exhaust Treatment Solutions to Meet Environmental Compliance

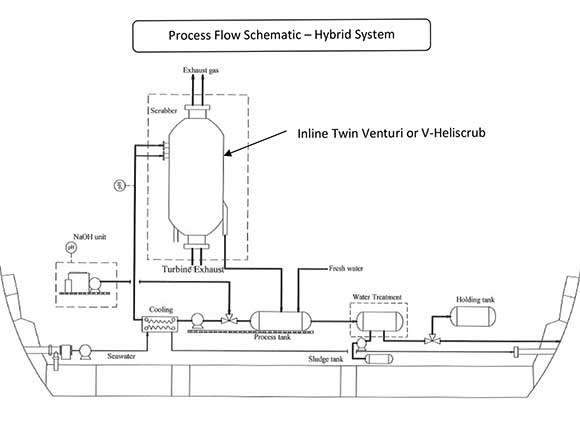

Inline Twin-Venturi Scrubber

- Superior design and performance

- Single scrubber can treat exhaust gas streams from ALL combustion sources - studies include Main & Auxiliary engines, and Auxiliary Boilers.

- Scrubber capacities up to 50 MW (higher capacity scrubbers available)

- More than 99% Sulphur removal efficiency with all fuel grades that ensures compliance with every Sulphur regulation, now and in the future

- Twin venturi model ensures greater than 99% removal of particulate matter

V-HELISCRUB- HORIZONTAL SCRUBBER

PROCESS FLOW DIAGRAM

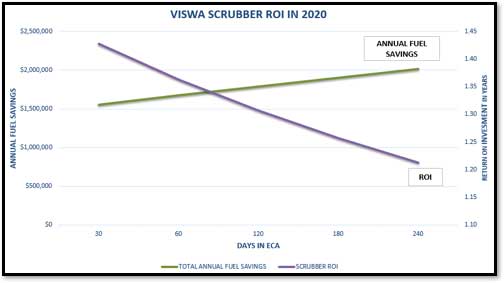

SCRUBBER FINANCIAL CALCULATIONS AND RETURN ON INVESTMENT (SHOULD FIT ON ONE PAGE

The installation of a Viswa Scrubber is one of the most cost-effective solutions to meet the regulatory requirements. Below calculations are based on a vessel with 10 MW Main Engine and 2 X 750 KW Auxiliary Engines consuming 32 MT/day.

| COST OF FUEL |

USD/MT |

| 3.5% S HFO |

300 |

| 0.5% S LSFO |

450 |

| 0.1% MGO |

500 |

| DIFFERENTIAL COSTS |

USD/MT |

| IN ECA (0.1% MGO - 3.5% HFO) |

200 |

| 0.5% S LSFO |

450 |

| NON ECA (0.5% LSFO - 3.5% HFO) |

150 |

The ROI is calculated based on the scrubber Capital Expenses (CAPEX) + the scrubber installation cost and the annual operating expenses (OPEX) including caustic, power, sludge disposal and maintenance costs.

For the 10 MW scrubber the ROI varies from 1.21 to 1.45 years. For a 20 MW scrubber the ROI will be just 0.8 to 1 year!

Notes

- Only a differential cost of USD 200 has been used between 0.1% MGO and 3.5% HFO. Many industry experts expect the differential cost will be USD 250 or even USD 300. This will mean much higher fuel savings and a much quicker ROI.

- Similarly, a differential cost of USD 150 has been used between 0.5% LSFO and 3.5% HFO. This is also expected to be higher.

- A rate of USD 300 per MT has been used for caustic in the OPEX costs. This is a variable cost and can be higher or lower.

The approximate scrubber and installation cost will be USD 2M

ADVANTAGES OF VISWA SCRUBBERS

| Feature |

Advantage |

| Design |

Higher allowable velocity and square design reduces the diameter by more than 50% compared to vertical scrubbers. |

| Horizontal Profile |

Self-balancing, No structural supports like vertical scrubber, stackable, occupies minimum foot space |

| Noise Reduction |

Proprietary internals are more effective than silencers |

| Installation |

Addition of dampers to existing duct, Avoids major changes to existing duct |

| Flexibility |

No Engine downtime, Bypass option, Maintenance ease while the engine is working, dry run capability |

| Weight |

Less than 50% weight compared to vertical, no impact on ship stability due to shape and weight |

| Pressure Drop |

Low pressure drop |

| Flue Gas Steam Heater |

Not required. Incoming Flue gas waste heat is utilized effectively |

| Quench Water |

Lower Consumption due to effective heat integration |

| Efficiency |

High PM removal and SO2 removal efficiency |

| Cost |

Low Opex and Capex due to inherent operation efficiency and design efficiency |